Características constructivas

EVAPORADOR

En su fabricación se emplean materiales homologados con las normas de calidad, y durante todo el proceso se verifica cuidadosamente cada operación. La tubería del evaporador está dispuesta en tres bolillos y el aletado de aluminio cuenta con un profundo corrugado para un mejor aprovechamiento del aire. Tanto las aletas como su fijación al tubo son efectuadas por máquinas modernas y precisas para poder obtener un alto coeficiente de transmisión.

GABINETE

El gabinete, de construcción autoportante, es de aluminio liso, pintado en blanco con pintura epoxi horneada, de acuerdo con las más exigentes normas sanitarias. La bandeja de desagüe es de fácil acceso para su limpieza.

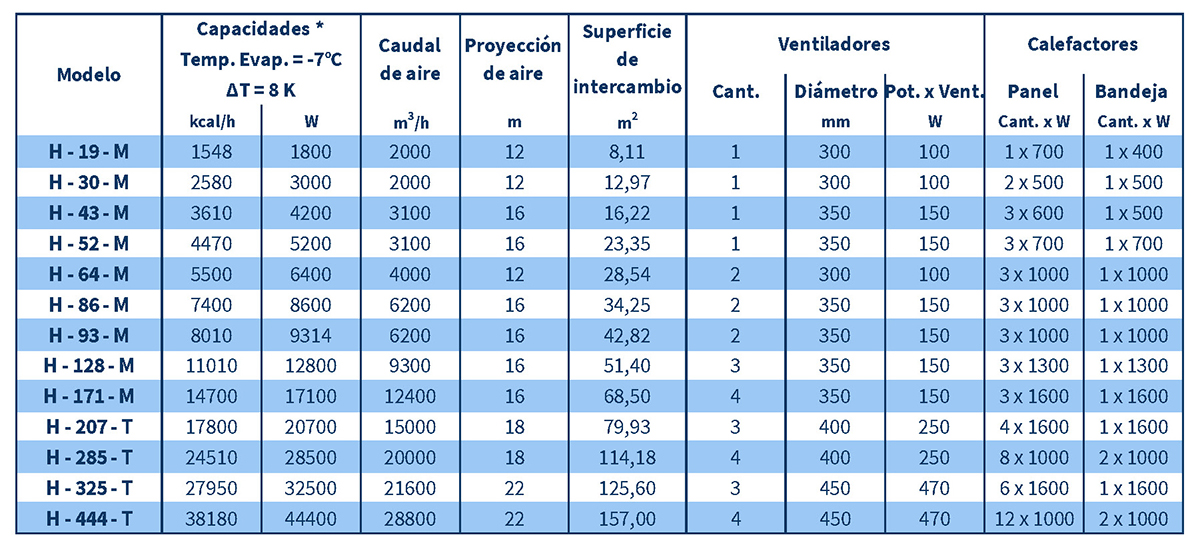

MOTOVENTILADORES

En todos los casos los caudales de aire fueron cuidadosamente estudiados en función de las superficies de transmisión para obtener una mayor eficiencia.

Todos los motoventiladores poseen protección IP-54 aislación clase B, son montados exteriormente, siendo los aeroevaporadores que tienen la característica M, monofásicos de 220 V y los que tienen T, trifásicos de 380 V / 50 Hz. A pedido podemos suministrarlos para otras tensiones y frecuencias.

En todos los casos son provistos con protector térmico de bobinado y están montados con rodamientos para bajas temperaturas. Las rejillas protectoras tienen acabado epoxi y son construidas bajo las normas de seguridad vigentes.

CALEFACTORES DE DESCONGELAMIENTO

Los calefactores son construidos en acero inoxidable, conectados y sellados en fábrica. Su tensión de trabajo es 220 V. Se instalan o retiran por una tapa lateral del equipo, y van solidarios a la batería en uno de sus extremos para evitar su desplazamiento por la dilatación.

Separación entre aletas 4,5 mm, tubo de 1/2″

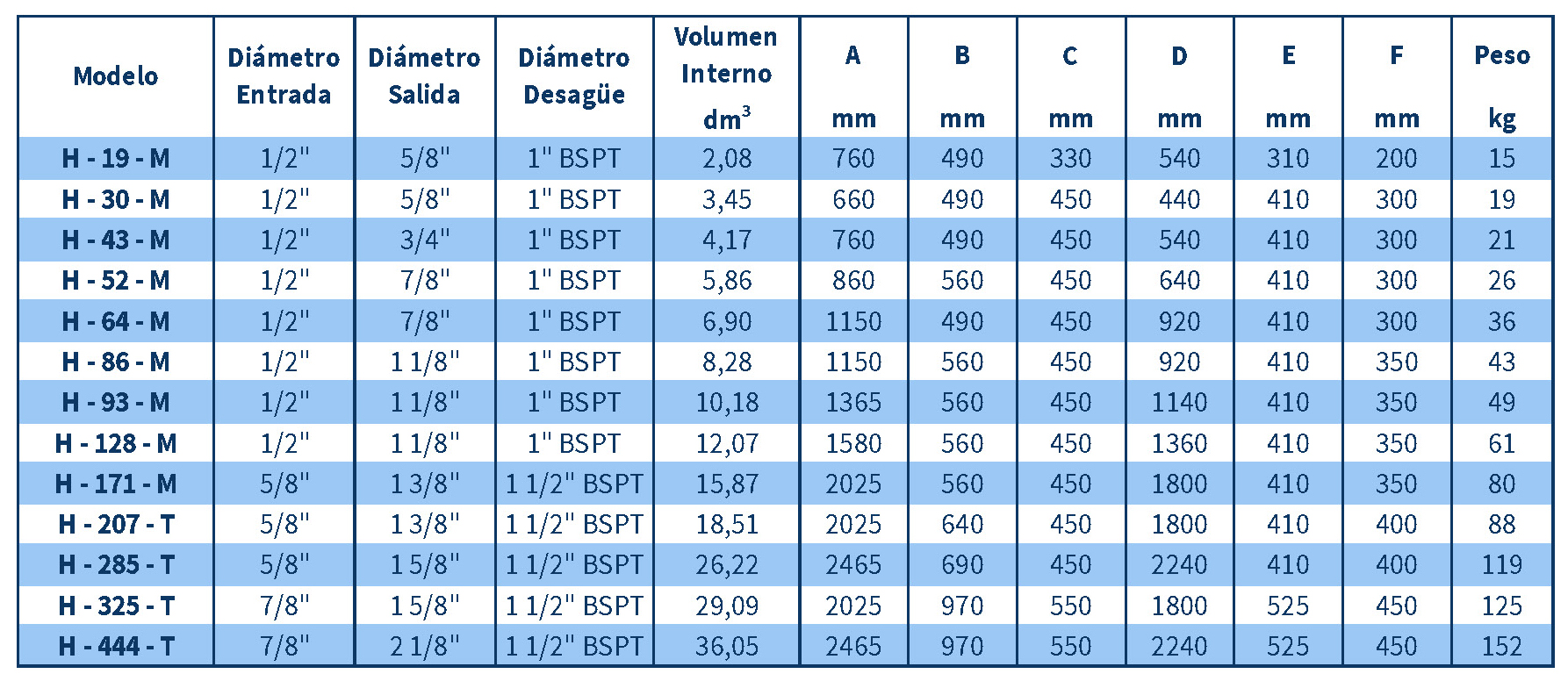

CARACTERÍSTICAS

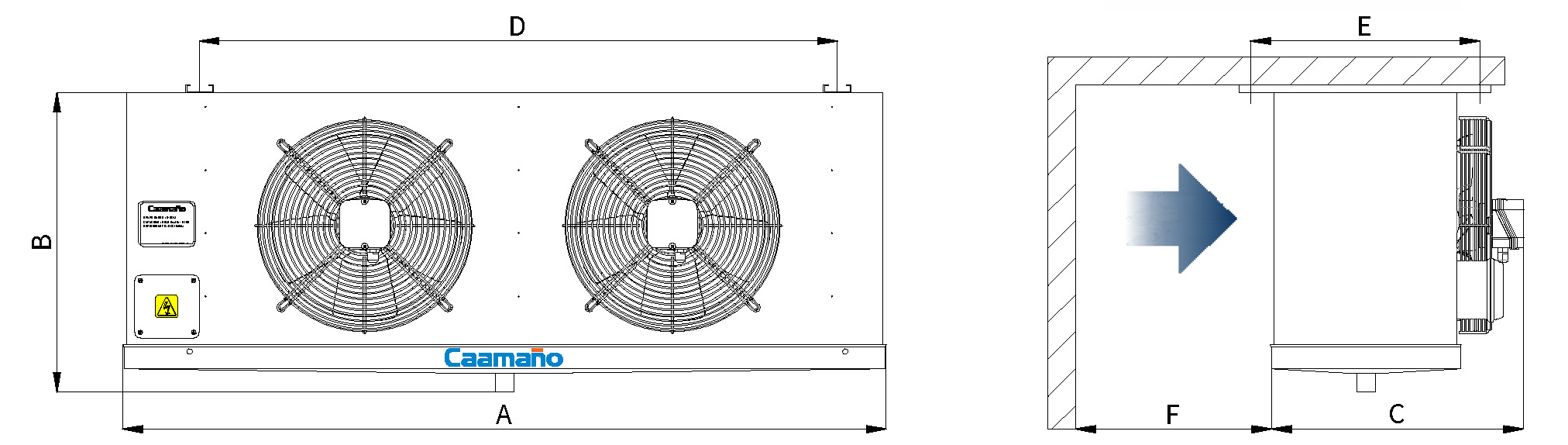

DIMENSIONES GENERALES